Sector

Marine

Location

United Kingdom - At Sea

Services

Remote Monitoring and Data Services

Our partnership with a leading cruise organisation

Overview

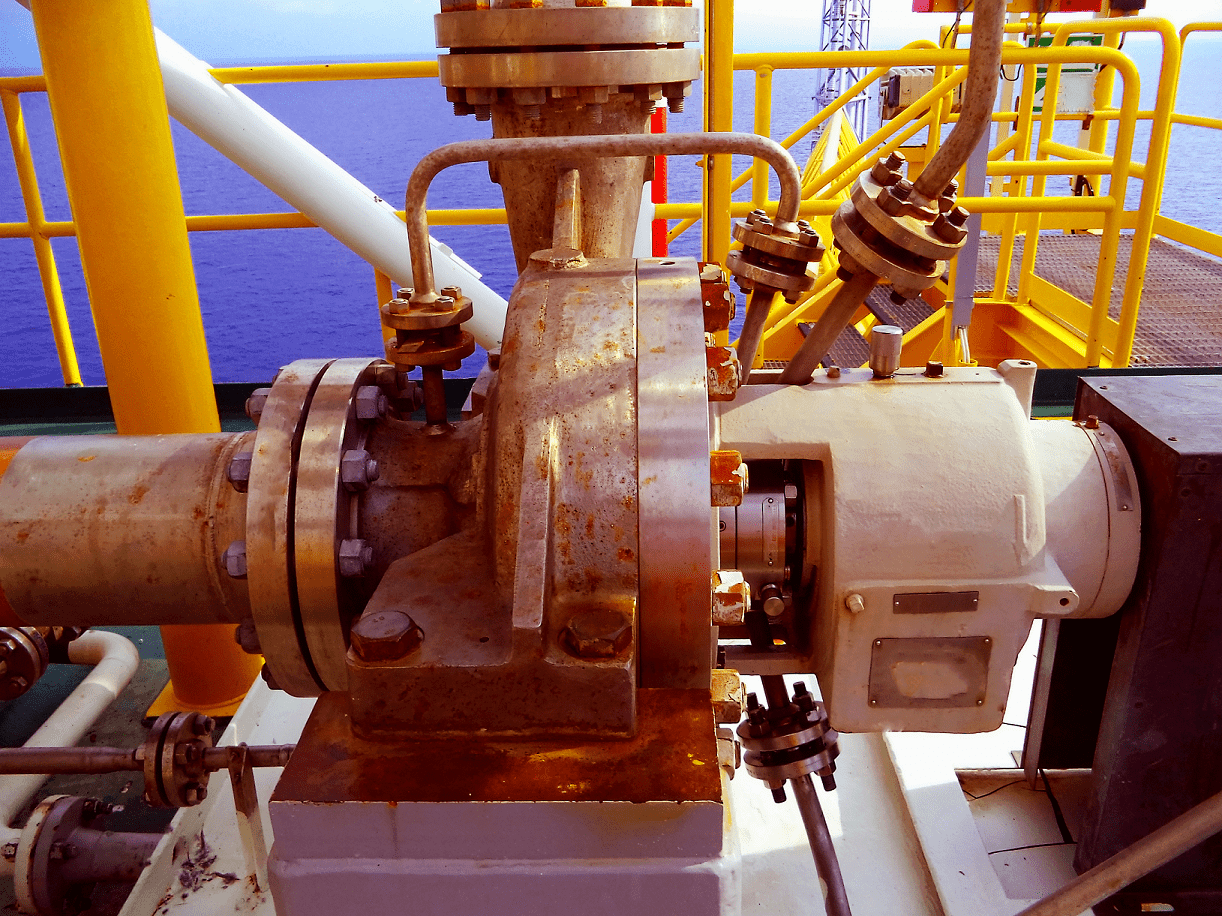

During the maiden voyage of a flag ship vessel, high vibration was experienced in the auxiliary system centrifugal cooling pump.

The vibration data uploaded into the Mimic condition monitoring system by the crew exceeded the pre-set thresholds set up by our experienced CM analysts. British Engineering Services Asset Reliability Mimic were contacted by the crew and requested assistance with root cause analysis.

This was especially important as prolonged high vibration in the auxiliary system centrifugal cooling water pump could have led to unplanned machinery failure.

The challenge

On-board a major cruise line’s flagship vessel, our condition monitoring system is installed across a range of critical assets, providing actionable insights into the condition and health of the machinery.

An issue was identified on a centrifugal pump that provides cooling to a number of the ships auxiliary systems. Vibration levels significantly exceeded pre-defined thresholds. Left undetected, significant damage could have been caused to the pump and linked auxiliary machinery, proving costly.

The solution

We supported our customer with:

Technology – our condition monitoring software identified vibration readings above pre-defined thresholds, forcing the system into alarm.

Remote analysis service – As part of the vibration data analysis service, our engineer provided direct feedback to the engineering crew on-board that identified the issue, the probable cause, and recommended corrective actions.

Proactive action – Following the insights that we provided, proactive action could be taken on-board, including the replacement of the pump’s bearings allowing the pump to operate within normal vibration thresholds.

The result

The early detection of an issue on-board the vessel prevented significant damage being caused to the pump and linked auxiliary machinery, saving money and increasing vessel reliability and performance.

The asset insights that we provided enabled the cruise operator to use its vessel data to make informed, proactive decisions to continuously improve its maintenance practices, increasing the lifespan of its fleet.

Utilised across the cruise operator’s wider fleet, our condition monitoring solution continues to ensure the avoidance of significant failures and unnecessary maintenance, highlighting the value and importance of condition-based maintenance.

Key outcomes

We helped to prevent damage to the pump and auxiliary machine

Saved money

Increased vessel reliability

Contact us to find out more about our Remote Monitoring and Data Services.

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team