Sector

Marine

Location

United Kingdom

Services

Remote Monitoring and Data Services

Condition Monitoring

Our partnership with a leading UK ferries operator

Overview

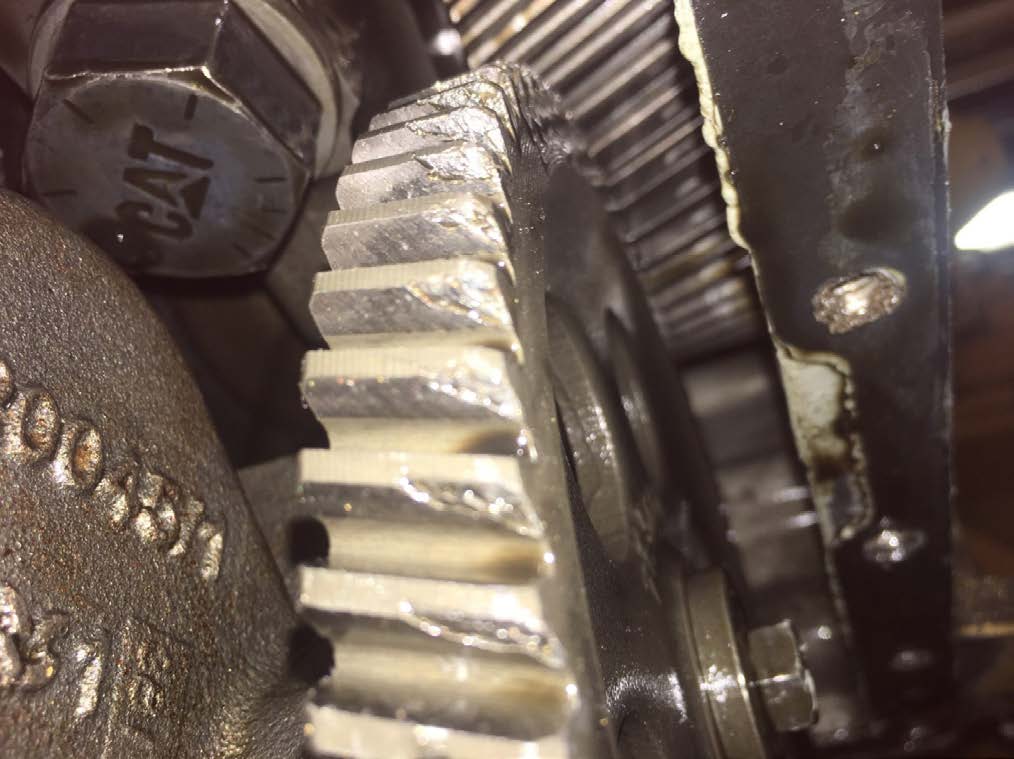

Whilst conducting routine vibration data analysis our highly trained and experienced analysis team identified a considerable increase in vibration amplitudes across the main engine lubrication oil pump.

Performing unnecessary maintenance can lead to wasted labour hours and spare parts. Planned maintenance can lead to maintenance-induced failure.

The challenge

The solution

The result

Scheduled planned maintenance is not always required due to the actual functioning condition of the machinery.

Condition Monitoring can identify early onset of machinery failure.

Importance of gaining Classification Society MPMS (CM) notation – the planned maintenance activity could be replaced by CBM, so maintenance would only take place when the condition of the machinery dictates.

Key outcomes

Maintenance strategy implemented.

Onset of machinery detection through Condition Monitoring.

Minimised risk for our customers and their people.

Contact us to find out more about Oil Analysis, Thermography Surveys and Remote Monitoring and Data Services.

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team