Sector

Manufacturing

Location

United Kingdom

Services

Remote Monitoring and Data Services

In-situ Balancing

Our partnership with a leading snack production facility

Overview

We detected an imbalance with machine through regular vibration analysis.

We provide routine bimonthly vibration analysis at a large snack production facility in the UK. As a Fast-moving consumer goods (FMCG) manufacturer, the early detection of failures is critical to keep production moving and to comply with strict regulations of the industry.

The challenge

The solution

After detailed analysis of the data, the engineer advised that the fan would require balancing at the next available opportunity that suited production demands.

Originally, it was thought that a build-up of product was causing the machine to be out of balance, but after thoroughly cleaning the fan the high vibration levels remained.

The site maintenance team instructed our engineers to balance the fan during a scheduled maintenance period.

The result

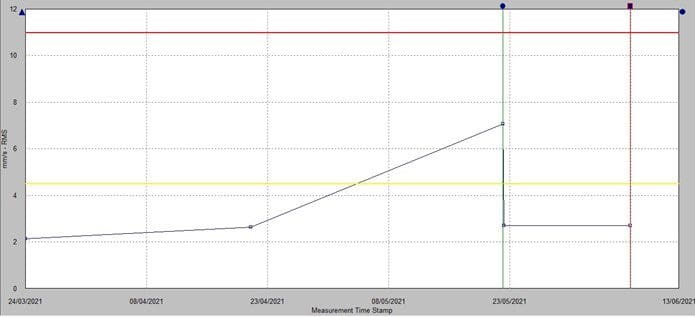

The balancing procedure required three separate trial weight and test runs to get the levels to an acceptable standard.

Before balancing, the overall vibration level was over 5mm/s with the highest been approximately 8.5mm/s across the fan.

Figure 1: Vibration data readings returning to normal levels after balance.

The completed balance showed operating levels of approximately 2.5mm/s across the unit – see figure 1. These levels have remained at an acceptable standard on future visits.

Many food and beverage companies are turning to condition-based maintenance to detect impending faults in machines early, enabling maintenance to be scheduled and significantly reducing the likelihood of an unplanned shutdown.

Key outcomes

We balanced the fan during a scheduled maintenance period.

Reduced overall vibration level from over 5mm/s to approximately 2.5mm/s.

Reduced the likelihood of an unplanned shutdown.

Contact us to find out more about Vibration Analysis, Remote Monitoring and Data Services and Products.

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team