Sector

Manufacturing

Location

United Kingdom

Services

Vibration Analysis

Remote Monitoring and Data Services

In-situ Balancing

Our partnership with an industry leading food manufacturer

Overview

We provide routine monthly condition monitoring services for a food manufacturer that specialises in the production of pre-packaged meals.

The main objective of the outsourced condition monitoring programme is to highlight equipment issues early to the site maintenance department, allowing maintenance activities to be scheduled during planned shutdowns.

The challenge

The solution

During a planned outage, our engineers inspected the fan and found the fan impellor was badly corroded and that the fan housing was wearing thin.

Loose material on the fan was removed and the fan was in-situ balanced. Initial data taken from the belt driven fan, which is inaccessible when online, showed high levels of 1x fan shaft vibration.

These readings confirmed that the high levels of fan speed vibration seen on the external motor readings was due to fan imbalance.

The result

Due to the condition of the fan housing, it was decided not to attempt to remove the bolts to open the inspection hatch and instead balance the fan by attaching the trial weights to the impeller where it was more accessible.

See Fig 1.

Figure 1: Non-drive end of the fan shaft

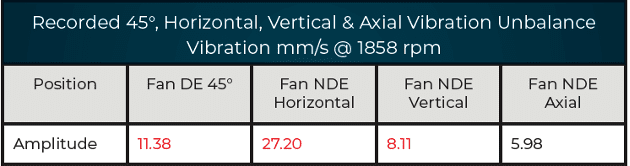

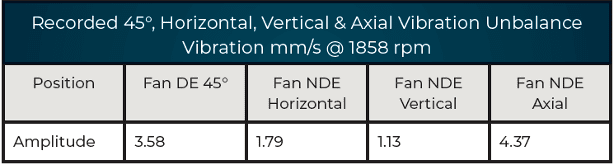

The balance procedure was then carried out which resulted in a 44g weight being attached to the impeller to correct the imbalance. Following the balance procedure, the fan was restarted, and a final set of readings taken from the fan. See table 1 and table 2.

Table 1 – Initial readings before balance

Table 2 – Readings after balance

A full balance report was produced and sent to the plant contact within two days of completing the balance procedure.

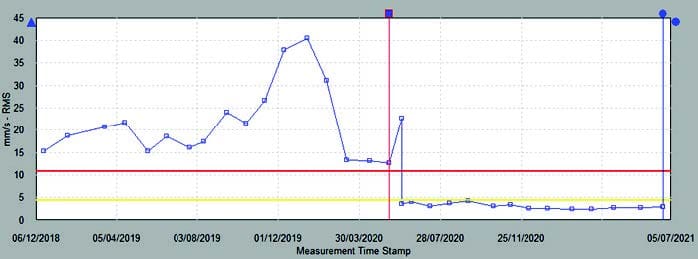

Monthly routine readings confirmed vibration levels have remained at an acceptable level, extended the life of the critical fan. See Fig 2.

Figure 2: Motor non-drive end velocity trend

Key outcomes

Prevented unplanned downtime.

Fan vibration levels returned to acceptable levels.

Life extension of the critical asset.

Contact us to find out more about Vibration Analysis, Remote Monitoring and Data Services and Products.

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team