Sector

Transport

Location

London

Services

Vibration Analysis

Remote Monitoring and Data Services

Products

Our partnership with Renold Gears

Overview

A condition monitoring survey on an escalator highlighted an inner race bearing fault on a worm box input shaft thrust bearing. By preventing an unexpected failure, it was estimated that the client saved £8,000 in repair costs and potential penalty fees.

We carried out a condition monitoring survey on two escalator drive gear trains at Tottenham Court Road tube station. The survey was performed on a newly fitted gearbox on behalf of a gearbox manufacturer in the UK.

The challenge

The solution

Standard vibration and stresswave data were collected by one of our reliability engineers using an Emerson 2140 Machinery Health Analyser.

The analyser was fitted with a 00mV/g accelerometer with a dual rail magnet mount.

The data was analysed, and a detailed report was sent to the client along with recommendations and feedback.

The result

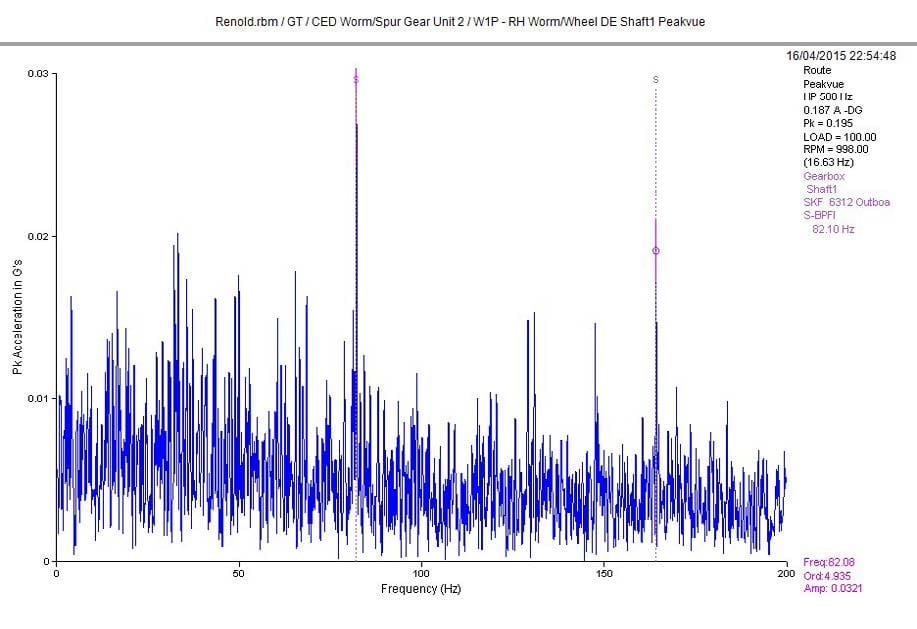

Analysis of the vibration and stresswave data revealed an inner race bearing fault on the RH worm box input shaft thrust bearing (6312) – see figure 1.

Figure 1: RH input shaft worm box stress wave spectrum.

While stresswave levels were low, due to the criticality of the asset the bearings were recommended for overhaul to prevent an in-service failure.

The bearing was replaced during scheduled maintenance by London Underground engineers.

By preventing an unexpected failure, it was estimated that the client saved £8,000 in repair costs and potential penalty fees.

As a result of the cost avoidance, the client recommended we carry out further routine monitoring on other escalators in the London Underground network.

Key outcomes

Detected inner race bearing fault on escalator worm box input shaft thrust bearing.

Recommended bearing overhaul to prevent in-service failure.

Bearing replaced during scheduled maintenance.

Estimated cost avoidance of £8,000.

Client recommended further routine monitoring.

Contact us to find out more about Vibration Analysis, Remote Monitoring and Data Services and Products.

Related Case Studies

View All Case Studies

Preserving History and Ensuring Safety with Structural Monitoring During The Jenners Building Re-development

Read more.

Vessel Downtime Avoided for UK Ferries Operator

Read more.

About BES Group

About BES Group Accreditations & Credentials

Accreditations & Credentials Our Environmental, Social & Governance

Our Environmental, Social & Governance Careers at BES Group

Careers at BES Group Our Senior Leadership Team

Our Senior Leadership Team